Remark

A、Main Parameters

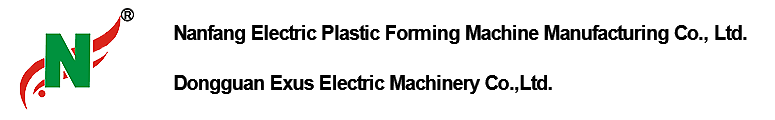

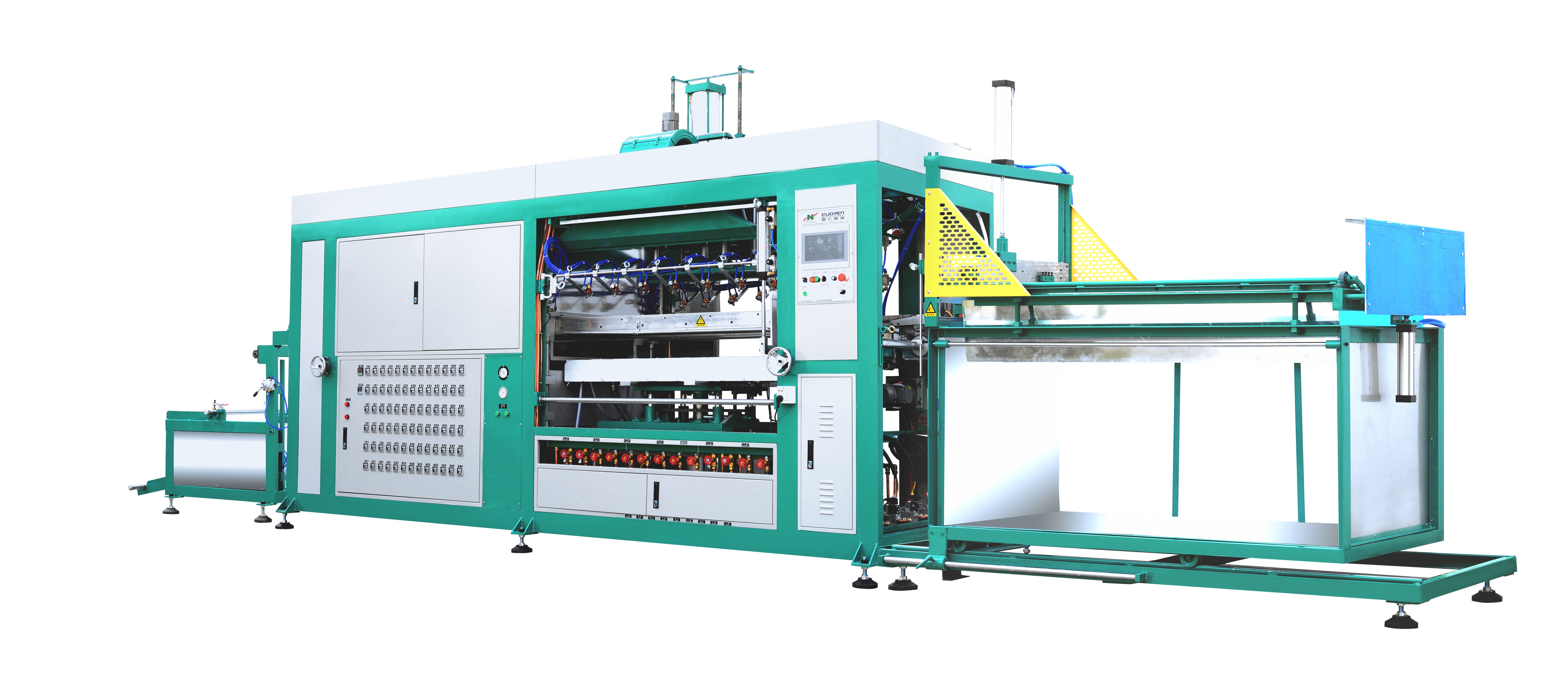

Model No.:

NF1250B

Forming Length:

300-1250mm (Arbitrary adjustment)

Forming Width:

410-760mm (Arbitrary adjustment)

Forming Height:

250mm (maximum)

Heater Max Power:

39KW (Max)

Vacuum Pump:(Brand HP & M3/H)

German vacuum pomp (100m³/H)

Air Pressure :

0.8Mpa

Machine Max Power:

47KW

Machine Dimension:

7500*2600*2630mm

Net Weight:

3800kg

Speed:

8-25s/time according to difference material

Material Thickness:

0.12--2.5mm

Material:

PVC, PE,PET, PC, PP, HIPS, APET, PETG, PS etc.

B、Main Configure:

Item

Description

Standard

Touch Screen:

MCGS 10” Touch screen, Kunlun on state

1pcs

Relay:

IDEC (Japan)

11pcs

AC Contactor:

Fuji (Japan)

4pcs

Heating System:

ELSTEIN (German) Far infrared ceramic heating brick (220V/400W/650W) with Japan KURABE high temperature cable.

60pcs

Solenoid:

CKD (Japan)

8pcs

Pneumatic Component:

CKD (Japan), SMC and high quality air cylinder to ensure the machine stability.

11pcs

Temperature Control:

Intelligent voltage regulators with digital indicators. One to one adjustment, Automatic and manual constant temperature is available.

60pcs

Vacuum Pump:

German vacuum pomp (100m³/H)

1pcs

Air Filter:

CKD(American) filter

1set

C、Application:

1. Making plastic packing covers of Toy, Hardware, Food, Electronics, Pharmaceuticals, Medical, Commodity, Apparels industry etc.

2. Making the plastic products with emboss, such as plastic ceilling, wallboard, cake box, automobile plastic material and Hygienic Material etc.

3. Making exquisite inner linning or outer packing to make the products looks refereshing and inprove the competitive ablility.

4. suitable for materials of PVC,PE, PET,PC,PP,HIPS,APET,PETG,PS, etc

5. Can be used to produce snack box, fruit tray, biscuit box, toothbrush, battery, gift, hardware, stationary, decorative article, plastic container, pill, etc.

6. This machine can be used to make various types of plastic material film formed into different shapes of plastic packing cover or products.

D、Feature:

1. This machine adopts motor pull film to reduce material loss and energy saving by fast pulling speed, easier to adjust material position and accurate pulling length, as well as improve product quality.

2. Independent Packet Temperature Control:

A. The temperature control of the heater is controlled by digital independent voltage regulation. Point-to-point display and controller with independent voltage stabilizing system to solve the problem of product quality caused by the fluctuation of power network voltage.

B. Digital pull out code intelligent voltage regulating display, Intuitive and stable, Realize the digital management of production, at the same time, it is convenient to monitor the whole process of production process.

C. In the normal production of the first batch of products, only need to record the process parameters in the production process of the product and re-input the same parameters of the production process when repeat produce the same products. The machine can produce the same high quality products as before no need to test again and reduce the waste of the material.

3. This machine with “PET Not Whited” system to solve the shortcomings of traditional plastic froming machine for PET,PP,PS and others materials, such as Low finished product rate and low production efficiency. This machine can adjust the position of electric furnace on horizontal. In the production can be based on the size of the mold to move the furnace position to control the heating area to save the power. Full closed heating furnace, so that more uniform heating, reducing the loss of heat energy.

4. This machine is equipped with cold air injection device to make full use of the mold plate to speed up the mold cooling when wait for the heating time. This can improve the quality of products.

5. Double needle chain drive to make sure high speed operation is still stable. Flexible length and width adjusting design to make the roll material could be used of the maximum rate and improve the quantity of products and reduce the material loss.

6. The machine is equipped with water cooling device and high speed cold water spray. So that it can speed up the forming speed and guarantee the forming quality.It’s 2 times speed compare to the traditional forming machine.

7. Engineering Roll Fed Vacuum Machines for a reliable high speed solution for vacuum forming company.